ECTIFIERS WITH SWITCH TECHNOLOGY

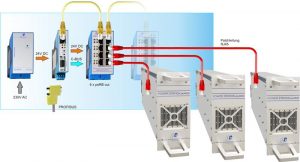

The high frequency technology offers many advantages compared to traditional rectifiers that work on the basis of an output adjustable by a motor control or a thyristor. The Switch mode is reliable, well known and appreciated for the solid technology underlying its operation. It is perfectly suited to the electrolytic industry. Rectifiers with air or water cooling are easily integrated into automated control systems.

MORE DETAILSADVANTAGES:

* on three-phase rectifiers

RECTIFIER WITH CASSETTE CONTAINER – POWER STATION up to 6 kW

AIR cooling

19 “RACK RECTIFIER MODEL – POWER STATION up to 24 kW

AIR cooling

DC Module Specifications:

VERSA POWER – Innovation and flexibility in sizing

The compact VERSA POWER system recently modified in design, offers individual combinations of voltage and current for each module. VERSA POWER is the ideal solution in response to the growing needs of electrolytic treatments. With just a few manual steps, each unit can be designed specifically for the customer. A VERSA POWER tower can reach up to 10 power modules and thus offer maximum flexibility in a minimum space.

| Number of modules | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Modules | 1200 A 600 A | 1 | 1 2 | 3 | 2 4 | 5 | 6 3 | 7 | 4 8 | 9 | 5 10 |

| DC voltage | 10 V 15 V 20 V 24 V 30 V | 600 A 600 A 600 A 500 A 400 A | 1200 A 1200 A 1200 A 1000 A 800 A | 1800 A 1800 A 1800 A 1500 A 1200 A | 2400 A 2400 A 2400 A 2000 A 1600 A | 3000 A 3000 A 3000 A 2500 A 2000 A | 3600 A 3600 A 3600 A 3000 A 2400 A | 4200 A 4200 A 4200 A 3500 A 2800 A | 4800 A 4800 A 4800 A 4000 A 3200 A | 5400 A 5400 A 5400 A 4500 A 3600 A | 6000 A 6000 A 6000 A 5000 A 4000 A |

VERSA POWER module specifications:

RACK RECTIFIER MODEL 19 “- POWER STATION

Water cooling.

DC module specifications:

RECTIFIERS WITH CABIN SOLUTIONS pe5000 – POWER STATION

AIR cooling

Cooling by water

* Increased performance through parallel connection of multiple devices

Cabinet solution specifications:

ACCESSORIES

Options:

Distributors / Resellers of the company PLATING ELECTRONIC GmbH.