Generators

Thanks to the use of very modern semi-conductors, complex integrated circuits and robust power electronics components, we are able to offer 19″ generators with a modular structure that meets the requirements of the industry. An extremely compact construction form allows a very small footprint The vibration units are chosen according to the individual needs of the customer.

TECHNICAL FEATURES:

Automatic adaptation.

Output power adjustable between 40% and 100% of the nominal power of the ultrasonic generator.

Automatic constant maintenance of the ultrasonic power that is actually emitted.

Ultrasonic generators with micropeocessors of the MI series.

The generator software allows extensive setting possibilities as well as an easy adaptation to superior process control systems. A special display shows the operating parameters in clear text. The setting and monitoring of the operating parameters are possible via integrated interfaces. An RS-232 serial interface is available and, as an option, an RS-485; the latter one allows a bus operation up to 247 generators. The related PC software for the configuration of the generators is available on request.

TECHNICAL FEATURES:

PushPull® transducer

The PushPull® transducer is a high-power bar-shaped vibration system that is urged to its two ends by ultrasound heads.

Even with increasing resonator length, the radial energy radiation ensures a very homogeneous acoustic field.

ADVANTAGES:

UNIVERSAL AND FLEXIBLE USE:

In these applications the PushPull® technique is a winner solution:

SinglePush® transducer

The SinglePush® transducer with a single sonic head is the least expensive variant of the PushPull® transducer. A single soundhead generates the full power of the ultrasounds.

ULTRASONIC CLEANING

Plate transducers

Plate transducers consist of a straight or articulated stainless steel membrane. The plate is fixed by welding frame, gasket and pressure frame from the outside, on a suitable passage in the cleaning tank. Plate transducers are available with 25kHz, 40kHz and 200kHz frequencies.

ADVANTAGES:

No reduction in the existing volume of the container

Homogeneous sound field thanks to the optimal arrangement of the vibrating elements.

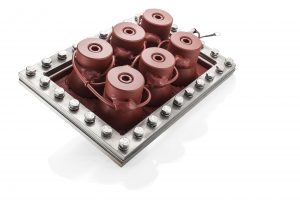

Immersible transducers

Our standard immersible transducers are made of high quality stainless steel. Other more suitable materials are available for the use of aggressive cleaning liquids. The frequency ranges are 25kHz, 40kHz up to 200kHz. All the vibration elements are staggered on the surface of the vibrating membrane according to a fixed pattern.

ADVANTAGES:

Homogeneous sonic field thanks to an optimal arrangement of the vibration elements

Possibility of different mounting solutions

Patented Ceramics elements

Thanks to an intense research activity at the Crest group headquarter, the Ceramics elements were invented and patented. The Ceramics elements allow the common effect of different frequencies as well as the combination of strength and effect, of depth, so as to achieve an optimal result in microscopic cleaning.

ADVANTAGES:

Distributors / Resellers of the company MARTIN WALTER ULTRASCHALLTECHNIK AG.